Wanxiang A123 launches immersion-cooled semi-solid-state energy storage solutions

Chinese manufacturer Wanxiang A123 Systems Corp. has launched its Star Series semi-solid-state battery cells and Star River Series energy storage solutions, which it describes as the world’s first deep integration of semi-solid-state battery technology with immersion cooling.

The Star Series cells leverage proprietary technologies to fundamentally address electrolyte leakage and instability. In a widely publicized 10-needle puncture test, a 100 Ah semi-solid-state cell remained fully stable, showing no fire, no explosion, and no thermal propagation.

At the system level, the Star River Series employs full immersion cooling, maintaining cell temperature variance within 2 °C. This dual-layer protection combines material-level stability with active thermal isolation, creating a robust safety barrier against thermal runaway and ensuring reliable operation in extreme environments, the company said.

Beyond safety, the platform delivers strong economic performance. The system achieves over 10,000 cycles at room temperature and more than 7,000 cycles at 45 °C, while its superior high-temperature resilience reduces the Levelized Cost of Energy by approximately 15%, the manufacturer claims.

The Star River Series solution matrix addresses a range of application scenarios. For data centers, the platform features an 800 V HVDC architecture capable of serving as a primary power source. Outdoor cabinet solutions are engineered with IP68-rated protection to withstand extreme environmental conditions. Modular 5-foot containers facilitate offshore and logistics-constrained applications, while 20-foot container systems integrate multi-stage fire suppression and three-level battery management system protection for large-scale deployments.

Wanxiang A123 has also introduced a Wireless BMS and AI platform incorporating pressure-sensing technology, capable of identifying thermal runaway risks up to 10 minutes earlier than conventional monitoring systems.

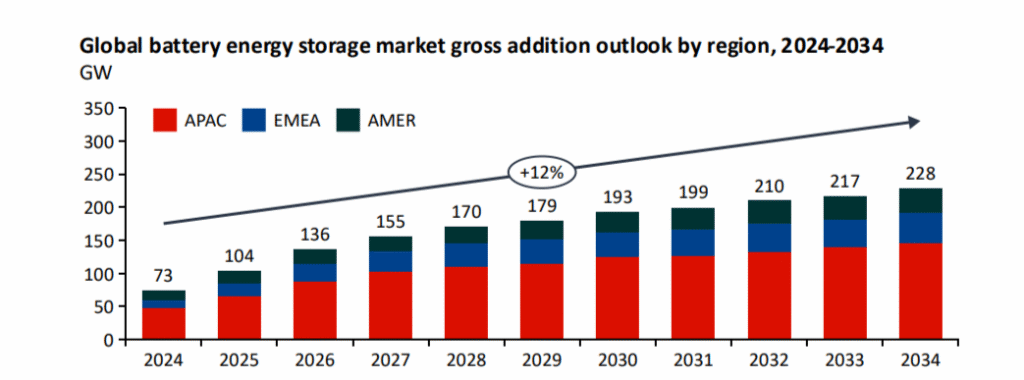

Semi-solid-state batteries have already reached a significant level of commercialization and are currently deployed primarily in electric vehicles, with some of the first grid-scale stationary storage projects coming online in China in 2024. While all-solid-state batteries still face major technical challenges for large-scale production and remain in the pilot stage, semi-solid-state batteries are already being manufactured at the GWh level.

These batteries use semi-solid electrolytes while retaining a small fraction of liquid electrolytes, enabling the incorporation of high-energy-density active materials. However, they still lag behind conventional liquid-electrolyte batteries in key areas such as cost, charge/discharge efficiency, and cycle life. Further improvements in cost reduction and performance optimization remain critical for their widespread adoption.

According to TrendForce, global demand for solid-state batteries, including semi-solid-state batteries, is projected to surpass 206 GWh by 2030 and exceed 740 GWh by 2035, signaling the beginning of large-scale commercial adoption.