Storing solar power through aluminum-rock composite

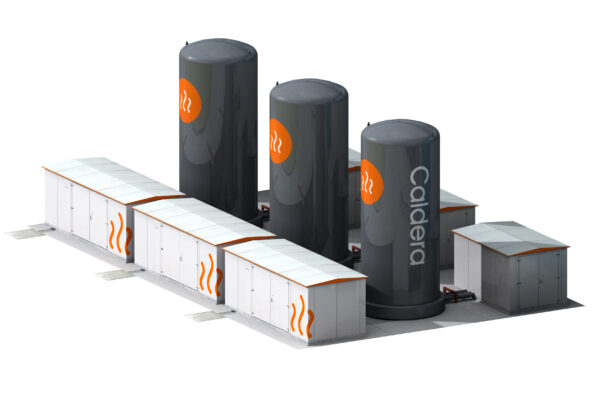

UK startup Caldera has developed a modular heat storage technology based on an earth-abundant aluminium-rock composite.

Called Megacell, the new storage tech is described as an ideal solution to decarbonize industrial processes and store photovoltaic energy generated on-site. The system’s rock-aluminum core is claimed to have the same thermal storage capacity as similar storage technologies based on rock, sand or concrete.

The system is a vacuum-insulated cell that can reportedly store heat at up to 500 C and produce hot water or steam at a temperature of up to 210 C. It consists of blocks made of a proprietary composite of recycled aluminum and volcanic rocks enclosed in a vacuum-insulated chamber.

The heat cell cores are encased in a vacuum flask and are heated using standard electric elements. “The vacuum prevents conduction and convection of heat, while an additional material prevents radiative losses, ” the company explains on its website. “A closed steam loop runs through each heat cell to maintain ultra-high purity and prevent eventual degradation from the build-up of solids.”

The company also claims its insulation takes up much less space, keeping the unit compact. “It is the cheapest and most efficient means of insulating the thermal core taking into account construction costs, insulation selection and weather proofing,” it states.

Caldera also explains that the system produces steam through a small quantity of water passed through a coil within the core. “This steam extracts stored energy from the heat cell, and varying the volume of water controls the power output,” it adds.

The company offers the cell with storage capacities of 1.3 MWh, 4 MWh, and 5.3 MWh, and with a steam generator, a compact substation, and a storage boiler. The smallest version measures 6 m x 14 m x 7.3 m and the largest has a size of 6 m x 14 m x 9 m. Its weight varies from 27 tonnes to 82 tonnes.

The modular approach allows combining multiple units and increasing a project’s storage capacity to up to 100 MWh, according to the manufacturer.

Caldera built the 4 MWh first demonstrator at its factory in Hampshire.