Production to disposal: Addressing toxicity in lithium batteries

Batteries have become a cornerstone of the global energy transition, powering not just electric vehicles but also supporting power grids and facilitating the decarbonization of buildings. The demand for efficient and safe energy storage solutions has skyrocketed as the world increasingly gets its energy from renewable sources. Alongside the surge in demand are significant investments from both government and the private sector, including the recent announcement from the Biden-Harris Administration of more than $3 billion in support for America’s battery industry.

Despite the historic momentum, the rapid proliferation of devices powered by lithium-ion batteries has brought significant safety concerns to the forefront. From e-bikes to electric vehicles to utility-scale energy storage, lithium-ion has revealed it has a flammability problem. Lithium-ion fires are often the result of thermal runaway, where battery cells generate more heat than can be dissipated, leading to buildup of gases and subsequent fire. Cities including New York and San Francisco have reported lithium-ion batteries as a leading cause of structure fires. Other urban areas around the world, particularly those with characteristically hot climates, grapple with similar issues concerning lithium-ion’s flammability.

While the flammability issue is out in the open, the challenge extends beyond just fire risks. Throughout their lifecycle, lithium-ion batteries pose additional toxicity risks that can threaten health and safety. As manufacturing and deployment capacity of the technology scales up, addressing the toxicity concerns of lithium-ion is paramount. The known hazards are also driving the search for innovative, non-lithium battery technology that can offer comparable performance without inherent toxicity or flammability.

Extraction

The human health toll from mining the materials necessary for lithium battery production is becoming difficult to ignore. Four of the core materials in modern “li-ion” batteries – lithium, nickel, cobalt, and copper – each come with their set of toxicity risks. Cobalt and copper mining in the Democratic Republic of Congo is well-documented as causing widespread health problems in nearby communities. In May 2024, scientists from the University of Lubumbashi tested water in rivers near the country’s largest mines and found them to be “hyper-acidic” or “very acidic.” This is leading to increased cases of skin, eye, and respiratory issues, and reproductive problems among women and children.

Coal-fired nickel smelters, such as the ones found in Indonesia, release carcinogenic sulfur dioxide into the air and communities near nickel mines and smelting operations are reporting elevated rates of birth defects and respiratory problems associated with exposure to pollution.

Much of the world’s lithium is extracted by tapping into underground brine deposits, pumping water rich in lithium salts into large evaporation ponds. By-products of the brine extraction process can include everything from sulfuric acid and radioactive uranium to lime and magnesium waste, all of which can increase rates of cancer and other diseases.

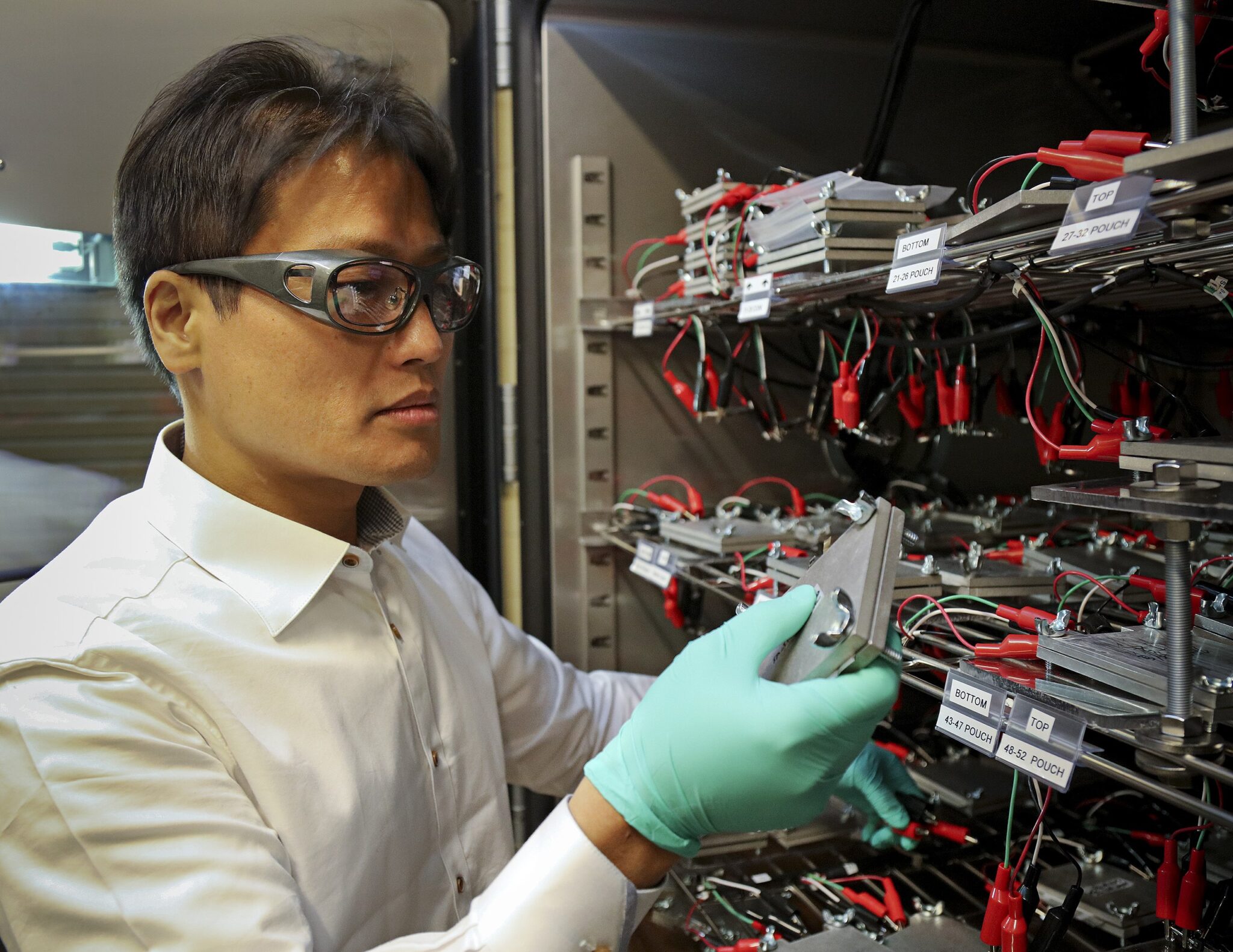

Battery manufacturing

At the manufacturing stage, facility workers face exposure to harmful chemicals including solvents, acids, and heavy metals. Long-term exposure to these substances can result in respiratory issues, skin conditions, and other health problems.

The organic liquids used in most electrolyte formulations are toxic; overexposure to lithium hexafluorophosphate (LiPF6) salts affects the digestive, circulatory, respiratory, and nervous systems, skin, and bones. Ingestion is the most dangerous path of entry into the body, but inhalation and skin contact can also be harmful.

Polyvinylidene (PVDF) polymers, widely used as binders in lithium-ion batteries, create health hazards during the recycling process. If heated in the absence of oxygen (using pyrolysis), PVDF binders release extremely dangerous hydrogen fluoride gas, which can cause blindness on exposure as well as convert to highly corrosive hydrofluoric acid in the presence of moisture.

During the dissolution phase, use of the solvent N-methyl-2-pyrrolidone (NMP) can irritate the skin and eyes and can make it difficult to breathe by irritating the lungs and respiratory system. The US Environmental Protection Agency describes NMP as a developmental toxicant, which is a toxin that interferes with growth and development. Extended exposure to NMP can also cause kidney and liver damage, neurotoxicity, and reproductive toxicity. Any exposure to NMP before or during pregnancy can result in fetal development problems, including decreased fetal weight and even death.

Per- and polyfluoroalkyl substances (PFAS), nicknamed “forever chemicals”, are another toxic compound associated with lithium-ion battery manufacturing. PFAS are particularly concerning due to their persistence in the environment and their potential to contaminate groundwater sources. In 2024, researchers found alarming levels of PFAS in the environment near lithium-ion manufacturing plants and where lithium-ion batteries were being disposed.

Operation

When they happen, the dangers of battery fires from systems deployed in the field extend far beyond the immediate flames. Another aspect is that when these batteries ignite or rupture they release an off-gas that can be extremely dangerous to human health and the environment. Among the most dangerous emissions is hydrogen fluoride gas, which can be fatal in atmospheric concentrations as low as 50 parts per million, as well as other harmful substances such as carbon monoxide and volatile organic compounds.

The large-scale battery fires that have occurred in the past year involved multi-day firefighter response efforts and emergency evacuations because of the atmospheric toxicity risk. While some toxic gases come from the plastic casings and other non-battery components making up a battery storage facility, the emission of hydrogen fluoride and hydrogen chloride are unique to lithium-ion batteries due to the chemicals inside them.

The methods available for fire suppression can be toxic, too. Some fire suppression chemical agents, such as aqueous film-forming foam, contain PFAS that can lead to long-term environmental health issues if discharged. Even fighting lithium-ion battery fires with water can cause contamination as the emissions from lithium batteries can combine with water to form toxic runoff that leeches into the soil and groundwater.

End of life

Lithium-ion batteries are classified as hazardous waste because of their high levels of cobalt, copper, and nickel, which exceed regulatory limits. Further, while capacity for recycling lithium-ion batteries is growing, the recycling methods and technology still rely on strong acids and solvents (such as sulfuric acid and hydrochloric acid) and presents another significant set of exposure hazards to recycling facility workers.

Though the industry’s shift to using lithium-ferro-phosphate (LFP) batteries has reduced the consumption of nickel and cobalt, LFP batteries have lower-value materials to be recovered via recycling, which may mean they get dumped instead of properly recycled. This has some very concerning implications for when large volumes of LFP batteries reach end-of-life.

Looking ahead

Through a combination of exploring alternatives and implementing robust safety measures, we can ensure that our path to a clean energy future isn’t paved with toxic and flammable technology. The emergence of non-lithium-ion battery chemistry demonstrates it is possible to balance the urgent need for energy storage with the equally critical requirements of non-flammability and non-toxicity. The list of non-flammable, non-toxic batteries entering the market can help to address many of the safety and environmental concerns associated with traditional lithium-ion technology.

From mining to manufacturing, operation, and disposal, lithium-ion batteries present serious threats to human health, worker safety, and ecosystems. While batteries are essential to the clean energy transition, it is imperative that we prioritize safer and more sustainable solutions. Only by addressing these challenges head-on can we ensure the energy system of the future is as clean as we say it is.

Mukesh Chatter is founder and CEO of Alsym Energy, a battery technology company developing high-performance, low-cost batteries to enable a zero-carbon electrified future. He is a serial entrepreneur with a track record of developing advanced technology products and leading startups from launch to success. Mukesh co-founded Nexabit Networks, a terabit switch/router company, and led the company as CEO until its acquisition by Lucent Technologies.

From pv magazine USA.