How to build the UK’s biggest BESS project

“People are busy and it’s raining all the time,” Henry Xu told ESS News – a concise summary of British project development from Sungrow’s Head of UK Energy Storage. This can be a challenging environment for any major construction job.

Sungrow has won the supply contract for what is set to be the largest UK BESS project to date, Thorpe Marsh. The project is one of two major utility-scale storage sites developed by UK based Fidra Energy that will be supplied through a 4.4 GWh BESS supply deal with the Chinese manufacturer.

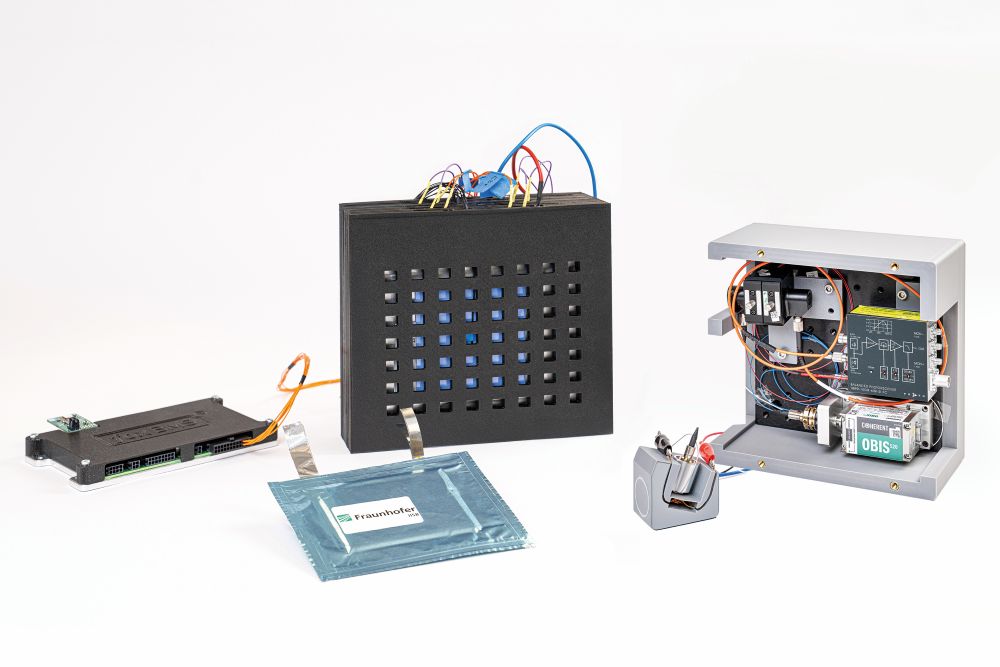

For Thorpe Marsh, Sungrow will ship 1.6 GW/3.3 GWh of its PowerTitan 2.0 BESS to the project site – meaning 3.1 GWh usable capacity for the developer. It’s a process that will require local market knowledge to overcome the location-specific challenges that come with building anything big in rural England.

Sungrow containers will need to make their way from port to a field in South Yorkshire. This demands close coordination with local authorities: there are country roads, low bridges and tight turns to navigate. Planning is paramount.

“In the UK, many people live in small towns which are close to each other,” Xu said. “Works needs to be arranged in a very efficient manner to cater for this.”

“At Sungrow, we have an internal logistic team that study the road conditions. Every time we do a big project in the UK we always do a road survey from our in-house logistic team.”

Sungrow carried out two road surveys for Thorpe Marsh. The logistics team also held discussions with local council to ensure access and to be able to carry out deliveries without needing a police escort.

When the BESS containers do arrive, Xu expects the construction process will be similar to Sungrow’s experience with the 100 MW/330 MWh Bramley BESS project, a UK project which entered commercial operation in February 2025.

Developed by BW ESS, Bramley BESS also uses the PowerTitan 2.0 BESS and Xu argued that because this is an AC-integrated solution with no exposed DC cabling, it reduces complexity during on-site construction.

“If you go to the Bramley site you will see exactly the same system typology. There’s no exposed DC cables, only AC cables and communication cables. That’s it,” he said.

Commissioning at Thorpe Marsh will be split into five phases, with some work running in tandem. The schedule is being optimized between Sungrow, Fidra Energy and principal designer and contractor H&MV Engineering. When it the first phase enters hot commissioning – when the system is connected to the main power source to run functional tests – the second phase will enter cold commissioning, a process that includes checking mechanical connections, cables and foundations.

Hot commissioning for phase one should take place before the end of 2026, according to Sungrow.

“By next Christmas, we will hopefully see snows on top of our some of the arrays. Probably the first array will be almost completed cold-commissioning and ready for hot-commissioning by next Christmas.”

Thorpe Marsh will be one of Europe’s largest BESS projects when commissioned and it has been backed by major private and state-owned investors.

Fidra Energy reached financial close on the Thorpe Marsh BESS in September 2025, securing GBP 445 million ($602 million) in equity funding. Backers included Fidra Energy’s founding investor EIG as well as the UK government-owned National Wealth Fund.

Sungrow has been able to build good relationships with UK developers and investors, according to Xu, in part due to its established UK workforce. The manufacturer has a UK staff count of around 100, including a local technical solution team, commissioning team and project managers.

“Compared with many suppliers that are not yet established here in the UK, if they don’t get local know-how to work with, and local support within the country, the experience would be completely different compared with when you talk to an established experienced supplier here like Sungrow.”

A diverse set of offtake agreements is now in place for Thorpe Marsh, including agreements with EDF, Octopus Energy and Statkraft, which cover around 80% of capacity. Thorpe Marsh has also been awarded a state-backed capacity market contract commencing October 2028.

As the technology provider, the offtake agreements themselves have nothing to do with Sungrow, but Sungrow did confirm the system design, typology and control logic “match exactly what the customer desires to do.”

This includes supplying an energy management system that was designed in a manner that allows all five arrays of Thorpe Marsh to work independently or cohesively, Xu said.

Xu added that because the power conversion system (PCS) deployed by Sungrow for its BESS projects is essentially the bi-directional inverter it puts in solar farms, the project is capable of participating in the stability markets that are developing in Great Britain’s, providing advanced grid ancillary services and some more future services such as inertia support.

“The detailed configuration changes project by project, but the technology remains. Our PCS can do many of these services, if not all, so this gives Fidra enough confidence in the future UK grid revenue environment – the system is also futureproof,” Xu said.