pv magazine’s guide to battery project contracts

pv magazine, in collaboration with Beñat Murua, senior project manager at Kiwa PI Berlin, has produced a guide to help developers and engineering, procurement, and construction companies negotiate contracts for battery energy storage systems (BESS).

The guide covers everything from defining owner requirements to contract negotiation and includes advice on how to analyze bid comparisons.

Owner requirements

In this first phase of a project, it is essential to prepare a document that includes the owner’s requirements. “This document must clearly and precisely establish the plant’s main technical requirements, especially regarding capacity and power,” said Murua. It must also specify the scope of supply and a system’s useful life.

Bidder documentation

The mandatory paperwork bidders must submit to participate in a tender must be clearly defined, including:

- A detailed economic proposal which includes a breakdown of the material included and not included in the supply deal and which defines milestones and payment percentages

- Technical specifications of the proposed BESS, including technical specs and features of all equipment

- Proposed guarantees of capacity, efficiency, and availability, among other parameters

- The scope of the project and services; responsibility matrix; materials; and personnel, defined by activity

- A maintenance plan

- An execution schedule

- A definition of the main equipment and material supply chain.

It is essential to precisely establish points where measurements will be taken to meet each technical requirement. For example, a manufacturer guaranteeing 4 MWh of direct current output from a BESS is not the same as a different manufacturer guaranteeing 4 MWh of medium-voltage, alternating-current output, after deducting losses in inverters and transformers. It is necessary to precisely indicate at what point in the system the capacity and power requirements must be met, as well as which equipment is included in the calculation of round-trip efficiency (RTE).

Scope of supply

The document must specify whether bidders will be responsible only for the BESS or whether they will also be required to supply auxiliary equipment such as power converters (PCs), transformers, medium-voltage cells, energy management systems, and plant controllers to hybridize a project.

Technical lifespan

The number of annual charge and discharge cycles a system will undergo should be defined, as well as expected technical lifespan. There are two possible approaches to this. In a conservative approach, capacity is required to remain constant throughout the entire service life, forcing bidders to oversize the system or propose a strategy of including additional capacity during the service life of the BESS via retrofitting. A degradative approach requires an initial capacity with progressive degradation acceptable.

In any case, bidders must be required to provide an annual table that includes guaranteed capacity, in megawatt-hours; guaranteed power, in megawatts; and guaranteed RTE, as a percentage.

Comparison of offers

Phase two of a project begins when the bidders have submitted the necessary documentation. “At Kiwa PI Berlin, we recommend comparing the bidders, dividing the analysis into three parts,” said Murua, with reference to economic, business, and technical analysis.

Economic

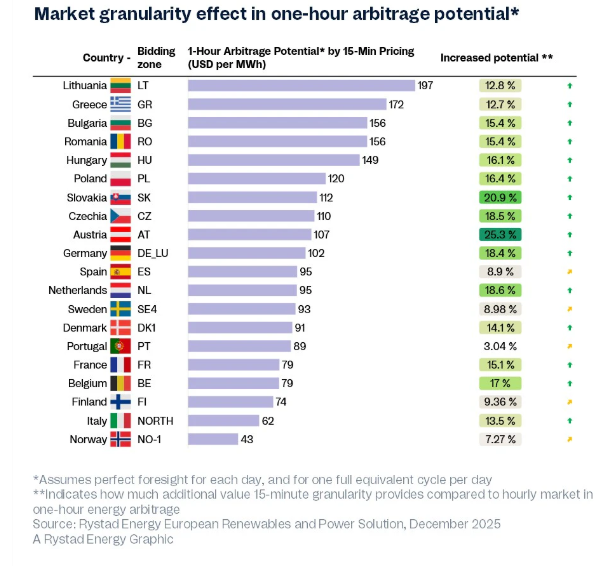

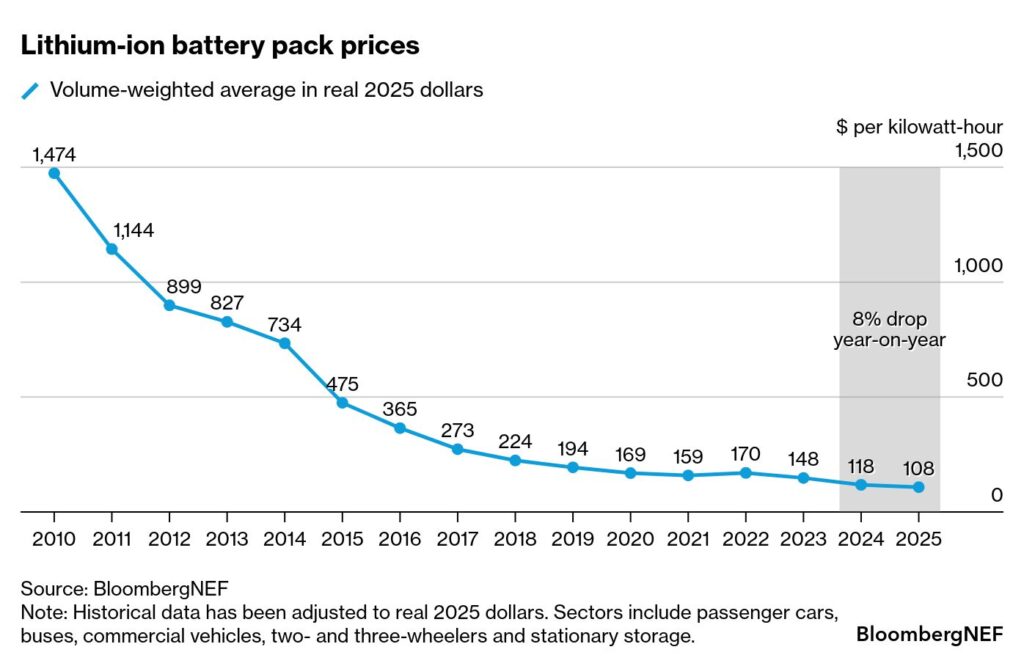

The economic appraisal of bids is based on project acquisition costs – as capital expenditure – and operating expenditure; full-cycle capacity and guaranteed RTE for each year of operation; and expected revenue from the energy and power supplied, based on historical data and market projections.

That information, with an appropriate discount rate will enable a calculation of net present value for each bid.

Business

Once all the information requested in the owner’s requirement document has been provided, analysis can take place of:

- The quality of the commercial offer: its validity, separation of materials and prices, requested program, and shipping terms

- The conditions for guaranteed capacity and efficiency: the testing time period, testing method, benchmarking, and contractual penalties

- The operation and maintenance proposal, scope, maintenance levels, and availability

Technical

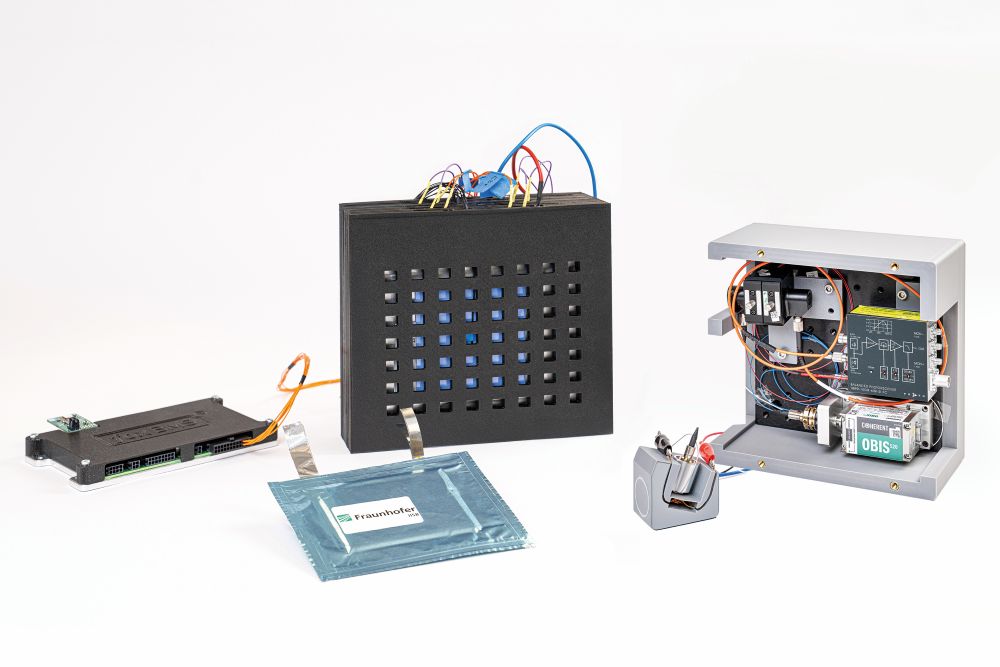

Independent analysis is performed for each of the system’s major components: battery cells, complete BESS, PCs, transformers, and medium-voltage cells.

The analysis includes:

- Manufacturer market experience: Years of operation, globally supplied equipment capability

- Compliance with standards and certifications, since different regulations apply to each component. For BESS, the UL9540 (or passing UL9540A testing), NFPA 855, and IEC 63056 standards are particularly relevant

- Power reduction levels, depending on the ambient temperature or operating altitude of the equipment as well as the level of protection against dust and water

- Equipment efficiency and harmonic distortion levels: the total harmonic distortion

Final analysis

In this phase, the scores obtained by each bidder in the different sections give an overall assessment. Each stage of the assessment is assigned a specific weighting relative to the total, as defined with the plant owner.

The justifications for each score are explained and the strengths and weaknesses of each proposal highlighted.

After completing technical, economic, and commercial bid analysis, the project owner selects one or more bidders to advance to the next phase of the process.

“Although it is possible to opt for a single bidder, it is best to select at least two bidders,” said Murua. “This strategy allows for flexibility during the negotiation phase, avoiding being locked into a single proposal, and fostering healthy competition that can improve the final terms of the contract.”

Contract negotiation

During the contract negotiation, technical exhibits play a key role. “These documents provide clear specifications for the requirements that the battery cells, BESS system, and power converters must meet, whether integrated into a single container or installed independently,” wrote Kiwa PI Berlin.

The exhibits can be used to draft or adapt the system procurement contract or can be added as an annex to it. In the latter case, it is important to ensure the contract and exhibits are aligned and do not differ on defined points.

Key aspects of contract negotiation include:

Supervised inspections

Inspections can be supervised by the owner or a third party designated by them, during different project phases. This includes factory audits, inspections during equipment manufacture, supervision of factory acceptance tests, and pre-shipment inspections of equipment.

Quality controls

Minimum quality requirements, and the controls to be followed to meet them, must be defined. These can include aging tests on battery cells, a maximum permitted deviation in capacity and internal resistance between cells, and a maximum self-discharge voltage under different environmental conditions.

Performance warranty

Minimum guaranteed values – such as total system capacity, loading and unloading efficiency, and availability, plus the conditions under which a BESS must operate – must be established by contract. Failure to meet minimum values will result in a performance guarantee which obliges the supplier to repair, replace, or provide financial compensation for any damage caused. Compensation levels must take into account expected profit from the plant although they usually have a cap, which is generally a percentage of total project cost.

Responsibility matrix

This key document should be thoroughly reviewed to ensure all parties comply with its scope. This is especially important to avoid discrepancies during equipment commissioning.

LTSAs

Long-term service agreements are essential to ensure continuous and efficient operation of a BESS. These contracts must address aspects such as service levels, the duration of the agreement, the responsibilities of each party, and incident response times.

From pv magazine España.