Faster, cleaner way to extract lithium from battery waste

Spent lithium-ion batteries can represent a source of valuable raw materials, but recovering processes for metals, such as lithium, are presently highly innefficient and economically unviable. Nonethelss, the exponential rise in the use of lithium-ion batteries has raised concerns over the supply chain of critical metals prompting a further search for optimized recovery strategies.

Now, a research team of Rice University in Texas, US, has reported a rapid, efficient and environmentally friendly method for selective lithium recovery using microwave radiation and a readily biodegradable solvent.

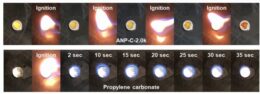

Their findings show the new process can retrieve as much as 50% of lithium from spent lithium ion battery cathodes in as little as 30 seconds, overcoming a significant bottleneck in the current recycling technology.

Namely, conventional recycling methods often involve harsh acids, while alternative eco-friendly solvents like deep eutectic solvents (DESs) have struggled with efficiency and economic viability. Moreover, current recycling methods recover less than 5% of lithium, largely due to contamination and loss during the process as well as the energy intensive nature of recovery.

“The recovery rate is so low because lithium is usually precipitated last after all other metals, so our goal was to figure out how we can target lithium specifically,” said Salma Alhashim, a Rice doctoral alumna and one of the study’s lead authors. “Here we used a DES that is a mixture of choline chloride and ethylene glycol, knowing from our previous work that during leaching in this DES, lithium gets surrounded by chloride ions from the choline chloride and is leached out into solution.”

The ultrafast selective lithium leaching can be attributed to microwave irradiation-induced preferential non-thermal activation of the polar choline chloride in the DES. “The rapid microwave approach allows time and energy-efficient recovery of Li and also prevents the degradation of DES, as is seen in conventional prolonged high-temperature procedures, and is able to extract Li from high solid/liquid concentrations of LIB cathodes in DES,” the researchers reported.

Compared to conventional heating methods like an oil bath, microwave-assisted heating can achieve similar efficiencies almost 100 times faster. For example, using the microwave-based process, the team found that it took 15 minutes to leach 87% of the lithium as opposed to the 12 hours needed to obtain the same recovery rate via oil bath heating.

“Using microwave radiation for this process is akin to how a kitchen microwave heats food quickly. The energy is transferred directly to the molecules, making the reaction occur much faster than conventional heating methods,” said Sohini Bhattacharyya, the other lead author on the study.

The researchers believe their method could significantly improve the economics and environmental impact of lithium-ion battery recycling, providing a sustainable solution to a looming global issue.

“This method not only enhances the recovery rate but also minimizes environmental impact, which makes it a promising step toward deploying DES-based recycling systems at scale for selective metal recovery,” said professor Pulicker Ajayan, the research team lead

The research findings are further discussed in Microwave Assisted Ultrafast, Selective Lithium Extraction in Deep Eutectic Solvent for LIB Cathode Recycling published in Advanced Functional Materials.