Li-Cycle’s battery recycling facility wins $475M loan from Department of Energy

In a win for the US battery recycling sector, Li-Cycle Holdings announced that it has secured a $475 million loan facility from the US Department of Energy’s (DOE) Loan Programs Office.

This landmark financing will support the development of Li-Cycle’s facility in New York state dubbed its Rochester Hub, which the company said would become North America’s first “commercial hydrometallurgical resource recovery facility.”

It would then become a significant domestic source of recycled critical materials for producing lithium-ion batteries, including battery-grade lithium carbonate and mixed hydroxide precipitate or MHP. MHP is an intermediate product containing nickel, cobalt, and manganese metals.

The DOE Loan Facility, which includes up to $445 million in principal and $30 million in capitalized interest, represents the first time the agency has provided financing to a lithium-ion battery recycler. This signals the DOE’s recognition of Li-Cycle’s pivotal role in building a sustainable, domestically-sourced battery supply chain.

“Securing the DOE Loan Facility is a strong endorsement of Li-Cycle’s recycling technology and its importance to the electrification transition,” said Ajay Kochhar, Li-Cycle’s President and CEO. “This financing will enable us to advance the Rochester Hub, which will be a significant domestic source of critical battery materials.”

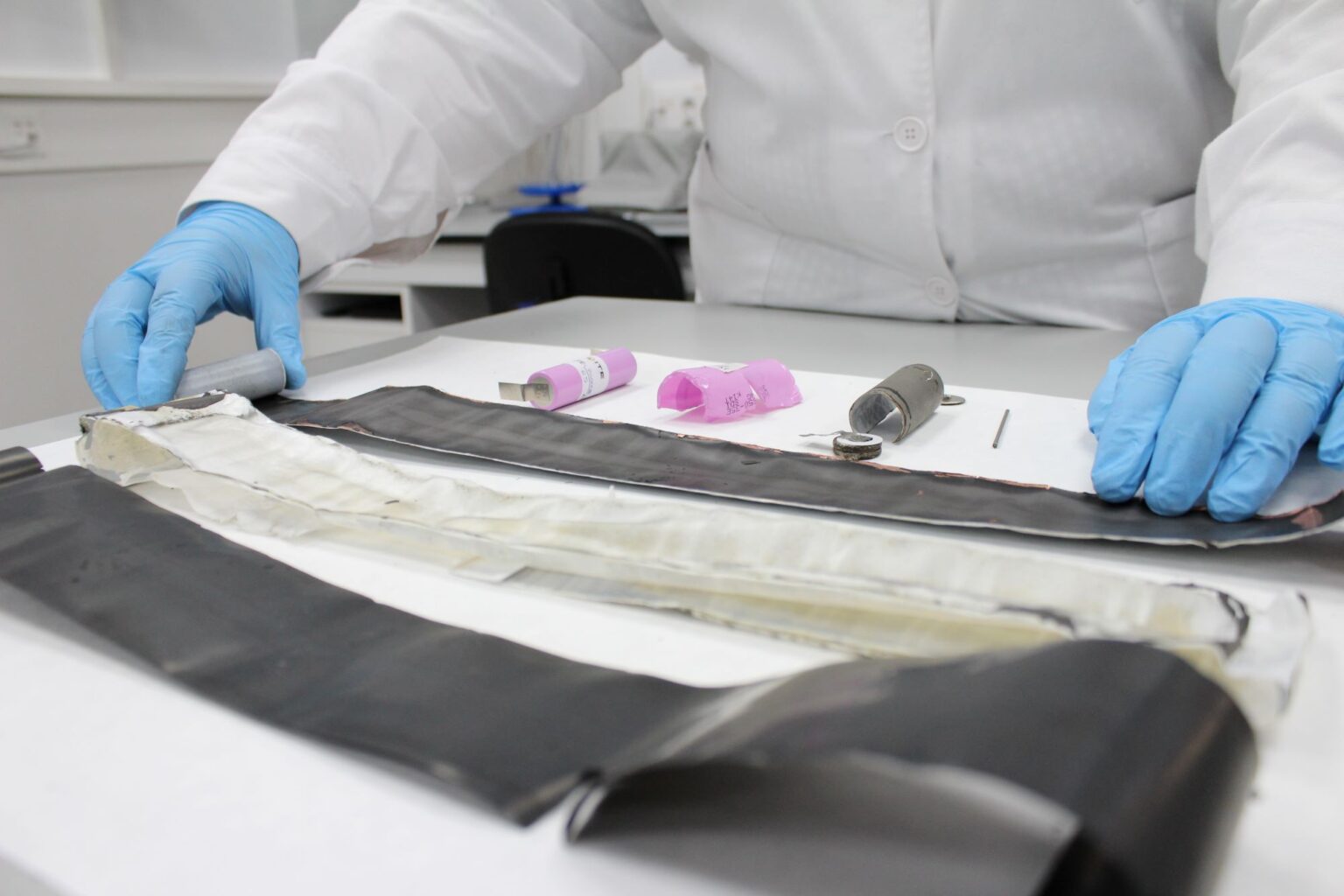

The company already has several facilities in operation known as spokes, where the first steps of battery recycling, known as pre-treatment, mainly take place. Hubs, like in Rochester, do the actual recycling and refinement of the raw materials occurs in the hubs

Once operational, the Rochester Hub is expected to produce up to 8,250 tonnes of battery-grade lithium carbonate and 72,000 tonnes of mixed hydroxide precipitate (MHP) annually. MHP is an intermediate product containing nickel, cobalt, and manganese – key materials for lithium-ion battery production.

The DOE’s technical, market, and financial due diligence process preceded the finalization of the loan agreement, underscoring Li-Cycle’s capabilities and the strategic value of its recycling model. With this DOE backing, the company is now actively pursuing additional financing to restart construction on the $960 million Rochester Hub project.

As the electric vehicle and energy storage markets continue to grow, sustainable battery recycling will be essential to securing North America’s battery supply chain for domestic manufacturing. The same is true in other areas such as Europe, where a recent report from Fraunhofer ISI detailed the evolving recycling chain for batteries in terms of spokes and hubs.