Enva unveils certified battery safe box to combat lithium battery fire risks

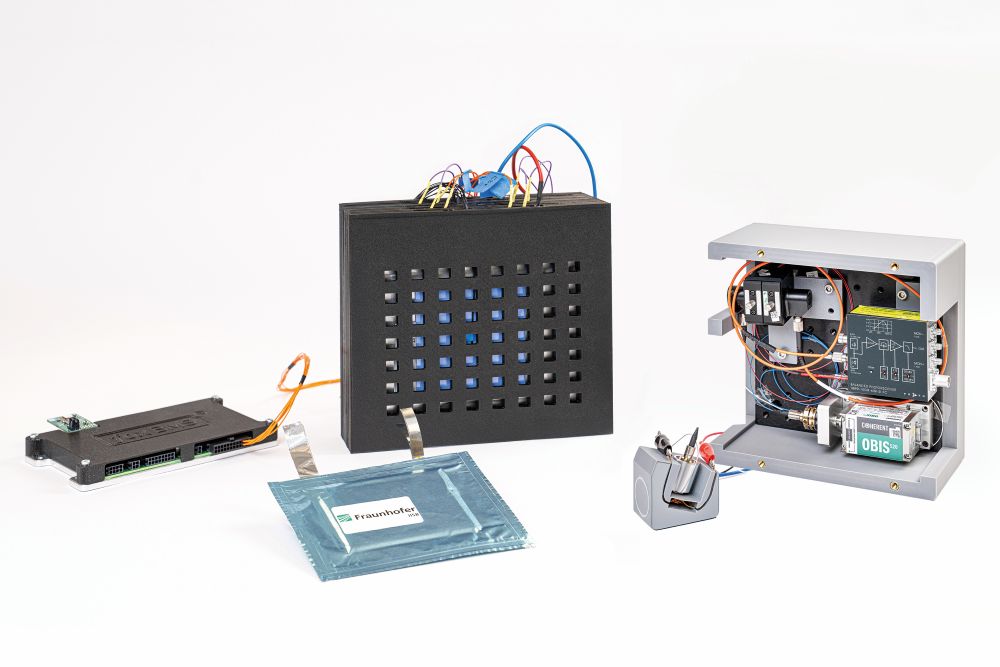

Recycling and resource recovery solutions provider Enva has launch a new ‘Battery Safe Box,’ a purpose-engineered solution for the safe storage and transportation of lithium battery waste, including defective units. The innovation comes as fires linked to lithium-ion batteries totaled 1,330 in 2024 in the UK alone according to QBE Insurance Group, highlighting safety and compliance needs across the clean-tech sector.

Capable of holding up to 400kg and 20 kWh of lithium batteries, the Battery Safe Box is certified under UN Dangerous Goods Packing Instruction P911 and has passed rigorous testing from the Vehicle Certification Agency (VCA), including fire containment and drop impact trials.

Managing director Mike Sneath said that Enva was committed to helping their clients safely dispose of lithium-ion batteries.

“This new Lithium Battery Safe Box reflects our commitment to safety, sustainability, and compliance,” Sneath said.

“It provides a reliable, approved solution for the secure storage and transport of hazardous lithium batteries, helping our clients manage their waste safely and efficiently.”

Enva’s Battery Safe Box features include Class 1 fire-resistant insulation, front-loading access for safer battery handling, and forklift and pallet truck access slots on all four sides. A stackable design allows three units to be stacked, enhancing space efficiency during transit, while the L-shaped Gas Lift Lid reduces operational difficulty and minimizes the risk of mishandling.

Fire suppression remains at the forefront of the industry for lithium-ion battery fires. Another hazard being offered new solutions is toxic gas release during thermal runaway events. In June 2025, EticaAG launched HazGuard, a new system designed to intercept and neutralize harmful gases before they pose significant environmental or occupational risks.