Japan’s NGK discontinues manufacturing of sodium-sulfur batteries

At its Board of Directors meeting on October 31, 2025, Japanese ceramics manufacturer NGK Insulators announced that it had resolved to discontinue the manufacturing and sales of its sodium-sulfur (NAS) batteries under its Energy Storage Business and to stop accepting new orders.

The company estimates that the expenses related to this decision will be approximately ¥18,000 million (US$117 million), which is expected to be recorded as extraordinary losses in the fiscal year ending March 2026.

In its FY2025 First Half Results, NGK reported that it had been in discussions with BASF, its partner since 2019, to expand supply capacity and achieve cost reductions in response to anticipated growth in energy storage demand. However, these discussions were discontinued in September 2025.

NGK also noted that the ongoing development of demand for NAS batteries’ key features – long-duration and large-capacity energy storage – is expected to take time.

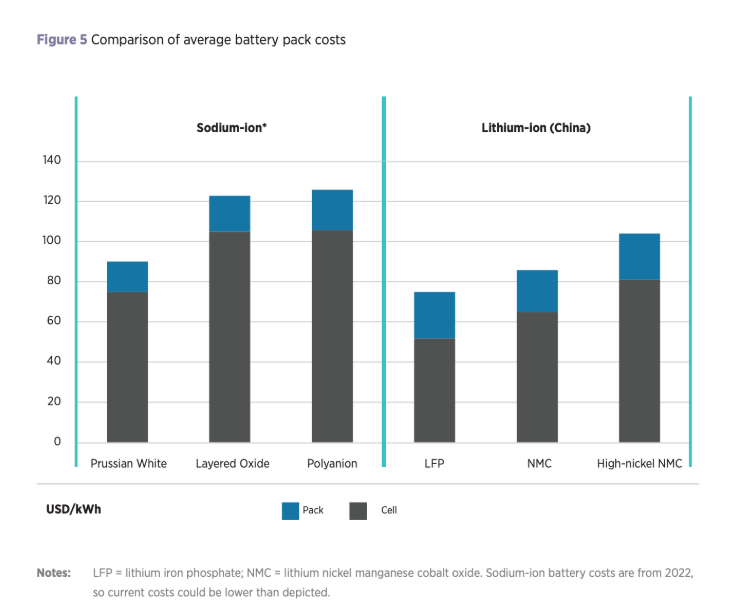

Furthermore, NGK said in the report that “the surges in material costs and intensifying competition with lithium-ion batteries” were making its business difficult. “Based on these factors, the Company has determined that stable operations and profitability will be difficult to achieve,” NGK said.

Long-duration applications, which have traditionally been the target of NAS batteries, are now increasingly served by lithium-ion technology. NGK has been developing NAS batteries since the 1980s and was the first to commercialize a megawatt-class energy storage system using this technology. These batteries can deliver power for over six hours at their rated output and have been installed in more than 250 locations worldwide, with a total capacity of around 5 GWh.

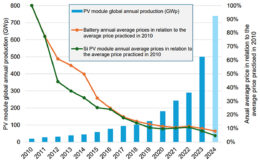

However, after rapidly improving their levelized cost of storage (LCOS) in recent years, lithium-ion systems can now efficiently provide even eight hours or longer of storage, encroaching on NAS batteries’ market share.

Going forward, in response to already accepted projects, NGK will proceed with shipments and deliveries from existing inventory once each customer’s intent is confirmed. For projects that are about to be ordered, deliveries can also be fulfilled from existing inventory. Additionally, the company will continue to responsibly supply maintenance parts for products that have already been delivered or are scheduled for delivery.

Technology

NAS batteries consist of sodium as the negative electrode and sulfur as the positive electrode. A beta-alumina solid electrolyte (BASE) allows only sodium ions to pass through. During discharge, sodium is oxidized at the anode, and sulfur is reduced at the cathode to form polysulfides. During charging, metallic sodium and elemental sulfur are regenerated.

NAS batteries have a calendar life of 20 years or 7,300 charge/discharge cycles, whichever comes first. Their strong selling proposition is high temperature tolerance of 300°C–340°C within a thermal enclosure. This makes them suitable for a wide range of ambient temperatures (-45°C to +55°C) without requiring air conditioning.

Last year, NGK and BASF Stationary Energy Storage, a subsidiary of BASF, launched a new version of their sodium-sulfur batteries. The containerized NAS MODEL L24, jointly developed by the partners incorporates several technological improvements. Compared to the previous model, the new NAS battery features a significantly lower degradation rate of less than 1% per year, achieved through reduced corrosion within the battery cells.