Czech company to provide cathode material to U.S. sodium-ion maker Natron Energy

Natron Energy, a spinoff out of Stanford University, has joined hands with Czech materials specialist Draslovka for the supply of Prussian blue cathode material required for its proprietary sodium-ion battery technology.

The R&D partnership agreement will fully utilize the Draslovka’s research, production and logistics capabilities on both sides of the Atlantic. Draslovka says it has also obtained the necessary permits and is well on its way to build a new reference facility for the project and expand its production capabilities at its operating chemical plant in chemical plant in Kolin, Czech Republic.

The facility will serve as a blueprint to expand Draslovka’s operations in the U.S., with the development of a large-scale facility expected to begin prior to the completion of the reference facility in Kolin.

“While today we are announcing a new plant at our EU location, we are already considering concrete options to build capability in the U.S. Additionally, we are evaluating opportunities for new production plants elsewhere in the U.S. to fully capitalize on the home-grown technological expertise we have at our flagship plant and as further demand for sodium-ion batteries is unlocked,” said Pavel Bruzek, CEO of Draslovka.

The new Kolin facility is expected to supply Natron with Prussian blue materials from 2026 onwards. This will allow the U.S. company to double its battery manufacturing capacity.

Wendell Brooks, CEO of Natron, said: “The battery industry is growing rapidly, and we are scaling our solutions as sodium-ion offers many advantages relative to lithium-ion technology for a wide range of customer use-cases, including data centers to support the explosive growth of AI.”

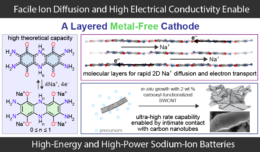

Natron’s revolutionary sodium-ion battery technology leverages Prussian Blue electrode materials to deliver “a high power, high cycle life, completely fire safe sodium-ion battery”. The company says that its patented Prussian blue structure does not expand and contract as it charges and discharges sodium ions. This “zero strain” mechanism results in greater chemical stability and avoids the particle degradation that limits cycle life in other batteries.

As a result, Natron’s batteries are touted to deliver 10x faster cycling than traditional lithium-ion batteries and 50,000+ cycle life. The company has also made claims that its sodium-based chemistry is more energy dense than lithium-based chemistries, which is atypical in this space.

For instance, other sodium-ion manufacturers, such as CATL, have revealed 160 Wh/kg sodium-ion batteries, with next-generation ambitions for 200 Wh/kg. Lithium iron phosphate (LFP) batteries range from 170 to 220 Wh/kg, and CATL’s nickel manganese cobalt (NMC)-based Qilin battery reaches 255 Wh/kg.

Technology claims aside, Natron Energy is one of the most promising players in the world’s sodium-ion battery space in terms of manufacturing ambition. In August 2024, the company announced plans to open a 24 GW annual production facility in North Carolina, creating over 1,000 jobs.

Sodium-ion battery tech has garnered a lot of attention in recent years. As lithium ion prices rose in 2022, amid predictions of material shortages, sodium ion was tipped as a rival and interest remains strong, even as lithium ion prices have started to fall again.

The two battery technologies have much in common in terms of structure and working principles and can often even use the same manufacturing lines and equipment. However, sodium-ion offers superior environmental credentials, enhanced safety, and better raw material costs than lithium-ion. Generally, Na-ion cells are quoted to be even up to 40% cheaper, but the challenge is bringing the technology to scale.